Analytical Solution for a 1D equilibrium interface

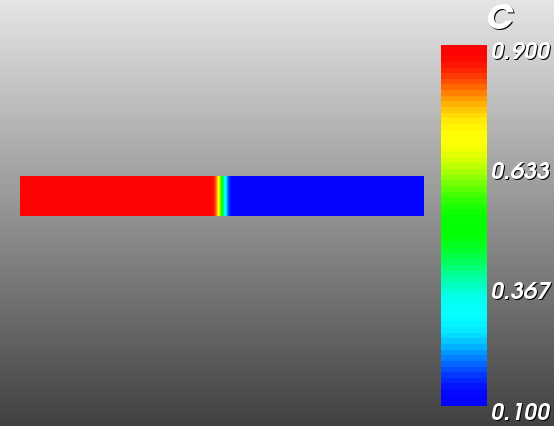

Composition for 2D simulation domain.

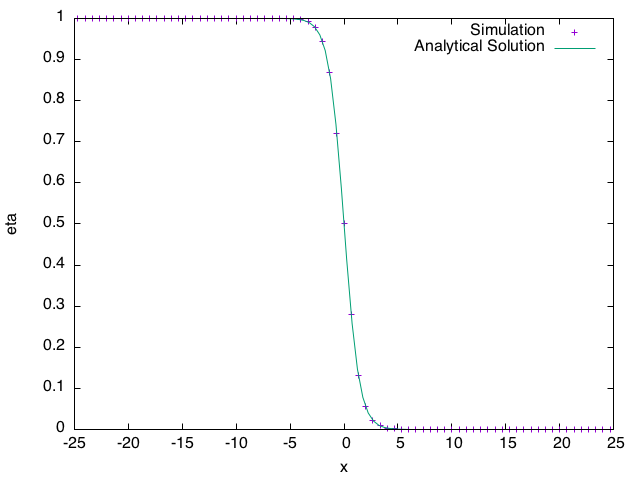

Order parameter along .

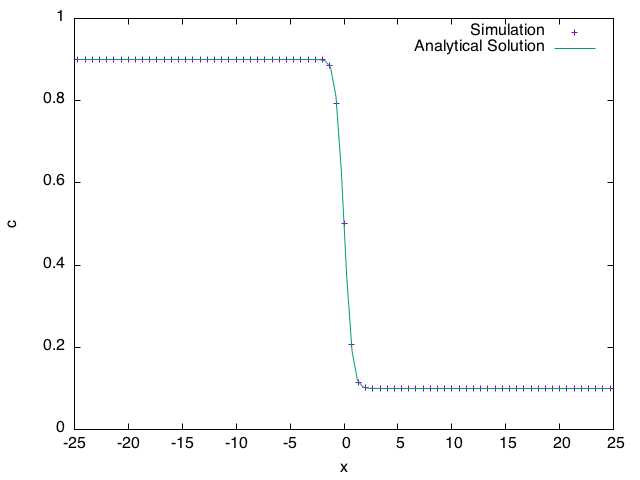

Composition along .

In the KKS model, an analytical solution exists for the order parameter and composition through a 1D equilibrium interface:

where we use the switching function , the gradient energy coefficient and the barrier function height . (Note that there is a typo in Eq. (49) of Kim et al. (1999), should be in the denominator of the argument to the function, not .) In the following example, we equilibrate a flat interface between a solid phase (, , ) and a liquid phase (, , ) in a 2D simulation. The vector postprocessor LineValueSampler is used to obtain the values of and along , the results are output to a CSV file, and plotted together with the 1D analytical solution. (We will use no-flux boundary conditions, so a boundary conditions block is not required in the input file.)

#

# KKS simple example in the split form

#

[Mesh]

type = GeneratedMesh

dim = 2

nx = 150

ny = 15

nz = 0

xmin = -25

xmax = 25

ymin = -2.5

ymax = 2.5

zmin = 0

zmax = 0

elem_type = QUAD4

[]

[AuxVariables]

[./Fglobal]

order = CONSTANT

family = MONOMIAL

[../]

[]

[Variables]

# order parameter

[./eta]

order = FIRST

family = LAGRANGE

[../]

# solute concentration

[./c]

order = FIRST

family = LAGRANGE

[../]

# chemical potential

[./w]

order = FIRST

family = LAGRANGE

[../]

# Liquid phase solute concentration

[./cl]

order = FIRST

family = LAGRANGE

initial_condition = 0.1

[../]

# Solid phase solute concentration

[./cs]

order = FIRST

family = LAGRANGE

initial_condition = 0.9

[../]

[]

[Functions]

[./ic_func_eta]

type = ParsedFunction

expression = '0.5*(1.0-tanh((x)/sqrt(2.0)))'

[../]

[./ic_func_c]

type = ParsedFunction

expression = '0.9*(0.5*(1.0-tanh(x/sqrt(2.0))))^3*(6*(0.5*(1.0-tanh(x/sqrt(2.0))))^2-15*(0.5*(1.0-tanh(x/sqrt(2.0))))+10)+0.1*(1-(0.5*(1.0-tanh(x/sqrt(2.0))))^3*(6*(0.5*(1.0-tanh(x/sqrt(2.0))))^2-15*(0.5*(1.0-tanh(x/sqrt(2.0))))+10))'

[../]

[]

[ICs]

[./eta]

variable = eta

type = FunctionIC

function = ic_func_eta

[../]

[./c]

variable = c

type = FunctionIC

function = ic_func_c

[../]

[]

[Materials]

# Free energy of the liquid

[./fl]

type = DerivativeParsedMaterial

property_name = fl

coupled_variables = 'cl'

expression = '(0.1-cl)^2'

[../]

# Free energy of the solid

[./fs]

type = DerivativeParsedMaterial

property_name = fs

coupled_variables = 'cs'

expression = '(0.9-cs)^2'

[../]

# h(eta)

[./h_eta]

type = SwitchingFunctionMaterial

h_order = HIGH

eta = eta

[../]

# g(eta)

[./g_eta]

type = BarrierFunctionMaterial

g_order = SIMPLE

eta = eta

[../]

# constant properties

[./constants]

type = GenericConstantMaterial

prop_names = 'M L eps_sq'

prop_values = '0.7 0.7 1.0 '

[../]

[]

[Kernels]

active = 'PhaseConc ChemPotSolute CHBulk ACBulkF ACBulkC ACInterface dcdt detadt ckernel'

# enforce c = (1-h(eta))*cl + h(eta)*cs

[./PhaseConc]

type = KKSPhaseConcentration

ca = cl

variable = cs

c = c

eta = eta

[../]

# enforce pointwise equality of chemical potentials

[./ChemPotSolute]

type = KKSPhaseChemicalPotential

variable = cl

cb = cs

fa_name = fl

fb_name = fs

[../]

#

# Cahn-Hilliard Equation

#

[./CHBulk]

type = KKSSplitCHCRes

variable = c

ca = cl

fa_name = fl

w = w

[../]

[./dcdt]

type = CoupledTimeDerivative

variable = w

v = c

[../]

[./ckernel]

type = SplitCHWRes

mob_name = M

variable = w

[../]

#

# Allen-Cahn Equation

#

[./ACBulkF]

type = KKSACBulkF

variable = eta

fa_name = fl

fb_name = fs

w = 1.0

coupled_variables = 'cl cs'

[../]

[./ACBulkC]

type = KKSACBulkC

variable = eta

ca = cl

cb = cs

fa_name = fl

[../]

[./ACInterface]

type = ACInterface

variable = eta

kappa_name = eps_sq

[../]

[./detadt]

type = TimeDerivative

variable = eta

[../]

[]

[AuxKernels]

[./GlobalFreeEnergy]

variable = Fglobal

type = KKSGlobalFreeEnergy

fa_name = fl

fb_name = fs

w = 1.0

[../]

[]

[Executioner]

type = Transient

solve_type = 'PJFNK'

petsc_options_iname = '-pc_type -sub_pc_type -sub_pc_factor_shift_type'

petsc_options_value = 'asm ilu nonzero'

l_max_its = 100

nl_max_its = 100

num_steps = 50

dt = 0.1

[]

#

# Precondition using handcoded off-diagonal terms

#

[Preconditioning]

[./full]

type = SMP

full = true

[../]

[]

[VectorPostprocessors]

[./c]

type = LineValueSampler

start_point = '-25 0 0'

end_point = '25 0 0'

variable = c

num_points = 151

sort_by = id

execute_on = timestep_end

[../]

[./eta]

type = LineValueSampler

start_point = '-25 0 0'

end_point = '25 0 0'

variable = eta

num_points = 151

sort_by = id

execute_on = timestep_end

[../]

[]

[Outputs]

exodus = true

[./csv]

type = CSV

execute_on = final

[../]

[]

Verification against analytical solution

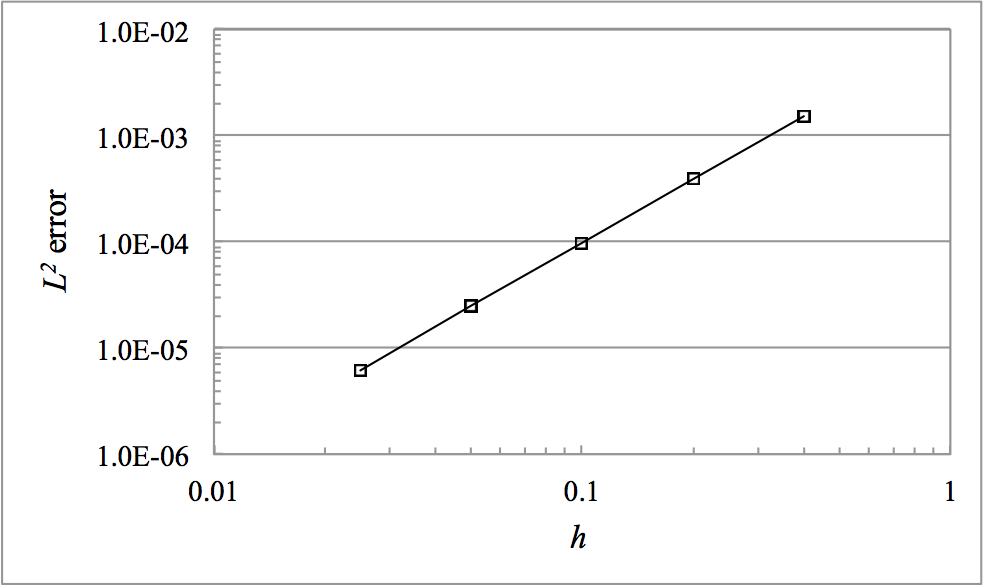

error for order parameter .

To perform a more quantitative comparison of the simulation results to the analytical solution, we will calculate the norm of the difference between the simulation result and the analytical solution. The norm is defined for this case as

where is the analytical solution, is the equilibrium solution from simulation, and is the domain. The norm can be obtained in the MOOSE framework using the ElementL2Error postprocessor. It can be shown from the properties of the finite element method that for the linear Lagrange elements used in the split formulation,

where is the characteristic element size (for 2D square elements, is the length of one side) and is a constant specific to the problem. Thus, as the mesh is refined, error should decrease (at least) quadratically with .

In performing this comparison between the analytical solution and simulation results, if a no-flux boundary condition is used in the simulation, the order parameter and composition profiles may shift slightly in the or direction, even if the analytical solution is used as an initial condition. This makes it difficult to compare to an analytical solution centered at . Therefore, we simulate the half of the domain and use a Dirichlet boundary condition of and at , which prevents the interface from moving. For the verification, the size of the domain was also reduced to lower the computational cost.

To verify that error decreases quadratically with , see the plot showing error versus for in this problem. As expected, on a log-log scale, the points are fit well by a straight line. The slope was determined to be 1.995, in good agreement with the expected value of 2.

#

# KKS simple example in the split form

#

[Mesh]

type = GeneratedMesh

dim = 2

elem_type = QUAD4

nx = 50

ny = 2

nz = 0

xmin = 0

xmax = 20

ymin = 0

ymax = 0.4

zmin = 0

zmax = 0

[]

[AuxVariables]

[./Fglobal]

order = CONSTANT

family = MONOMIAL

[../]

[]

[Variables]

# order parameter

[./eta]

order = FIRST

family = LAGRANGE

[../]

# hydrogen concentration

[./c]

order = FIRST

family = LAGRANGE

[../]

# chemical potential

[./w]

order = FIRST

family = LAGRANGE

[../]

# Liquid phase solute concentration

[./cl]

order = FIRST

family = LAGRANGE

initial_condition = 0.1

[../]

# Solid phase solute concentration

[./cs]

order = FIRST

family = LAGRANGE

initial_condition = 0.9

[../]

[]

[Functions]

[./ic_func_eta]

type = ParsedFunction

expression = 0.5*(1.0-tanh((x)/sqrt(2.0)))

[../]

[./ic_func_c]

type = ParsedFunction

expression = '0.9*(0.5*(1.0-tanh(x/sqrt(2.0))))^3*(6*(0.5*(1.0-tanh(x/sqrt(2.0))))^2-15*(0.5*(1.0-tanh(x/sqrt(2.0))))+10)+0.1*(1-(0.5*(1.0-tanh(x/sqrt(2.0))))^3*(6*(0.5*(1.0-tanh(x/sqrt(2.0))))^2-15*(0.5*(1.0-tanh(x/sqrt(2.0))))+10))'

[../]

[]

[ICs]

[./eta]

variable = eta

type = FunctionIC

function = ic_func_eta

[../]

[./c]

variable = c

type = FunctionIC

function = ic_func_c

[../]

[]

[BCs]

[./left_c]

type = DirichletBC

variable = 'c'

boundary = 'left'

value = 0.5

[../]

[./left_eta]

type = DirichletBC

variable = 'eta'

boundary = 'left'

value = 0.5

[../]

[]

[Materials]

# Free energy of the liquid

[./fl]

type = DerivativeParsedMaterial

property_name = fl

coupled_variables = 'cl'

expression = '(0.1-cl)^2'

[../]

# Free energy of the solid

[./fs]

type = DerivativeParsedMaterial

property_name = fs

coupled_variables = 'cs'

expression = '(0.9-cs)^2'

[../]

# h(eta)

[./h_eta]

type = SwitchingFunctionMaterial

h_order = HIGH

eta = eta

[../]

# g(eta)

[./g_eta]

type = BarrierFunctionMaterial

g_order = SIMPLE

eta = eta

[../]

# constant properties

[./constants]

type = GenericConstantMaterial

prop_names = 'M L eps_sq'

prop_values = '0.7 0.7 1.0 '

[../]

[]

[Kernels]

# enforce c = (1-h(eta))*cl + h(eta)*cs

[./PhaseConc]

type = KKSPhaseConcentration

ca = cl

variable = cs

c = c

eta = eta

[../]

# enforce pointwise equality of chemical potentials

[./ChemPotSolute]

type = KKSPhaseChemicalPotential

variable = cl

cb = cs

fa_name = fl

fb_name = fs

[../]

#

# Cahn-Hilliard Equation

#

[./CHBulk]

type = KKSSplitCHCRes

variable = c

ca = cl

fa_name = fl

w = w

[../]

[./dcdt]

type = CoupledTimeDerivative

variable = w

v = c

[../]

[./ckernel]

type = SplitCHWRes

mob_name = M

variable = w

[../]

#

# Allen-Cahn Equation

#

[./ACBulkF]

type = KKSACBulkF

variable = eta

fa_name = fl

fb_name = fs

w = 1.0

coupled_variables = 'cl cs'

[../]

[./ACBulkC]

type = KKSACBulkC

variable = eta

ca = cl

cb = cs

fa_name = fl

[../]

[./ACInterface]

type = ACInterface

variable = eta

kappa_name = eps_sq

[../]

[./detadt]

type = TimeDerivative

variable = eta

[../]

[]

[AuxKernels]

[./GlobalFreeEnergy]

variable = Fglobal

type = KKSGlobalFreeEnergy

fa_name = fl

fb_name = fs

w = 1.0

[../]

[]

[Executioner]

type = Transient

solve_type = 'PJFNK'

petsc_options_iname = '-pc_type -sub_pc_type -sub_pc_factor_shift_type'

petsc_options_value = 'asm ilu nonzero'

l_max_its = 100

nl_max_its = 100

nl_abs_tol = 1e-10

end_time = 800

dt = 4.0

[]

#

# Precondition using handcoded off-diagonal terms

#

[Preconditioning]

[./full]

type = SMP

full = true

[../]

[]

[Postprocessors]

[./dofs]

type = NumDOFs

[../]

[./integral]

type = ElementL2Error

variable = eta

function = ic_func_eta

[../]

[]

[Outputs]

exodus = true

console = true

gnuplot = true

[]

References

- Seong Gyoon Kim, Won Tae Kim, and Toshio Suzuki.

Phase-field model for binary alloys.

Physical Review E, 60(6):7186–7197, December 1999.

URL: http://link.aps.org/doi/10.1103/PhysRevE.60.7186 (visited on 2014-03-31), doi:10.1103/PhysRevE.60.7186.[BibTeX]